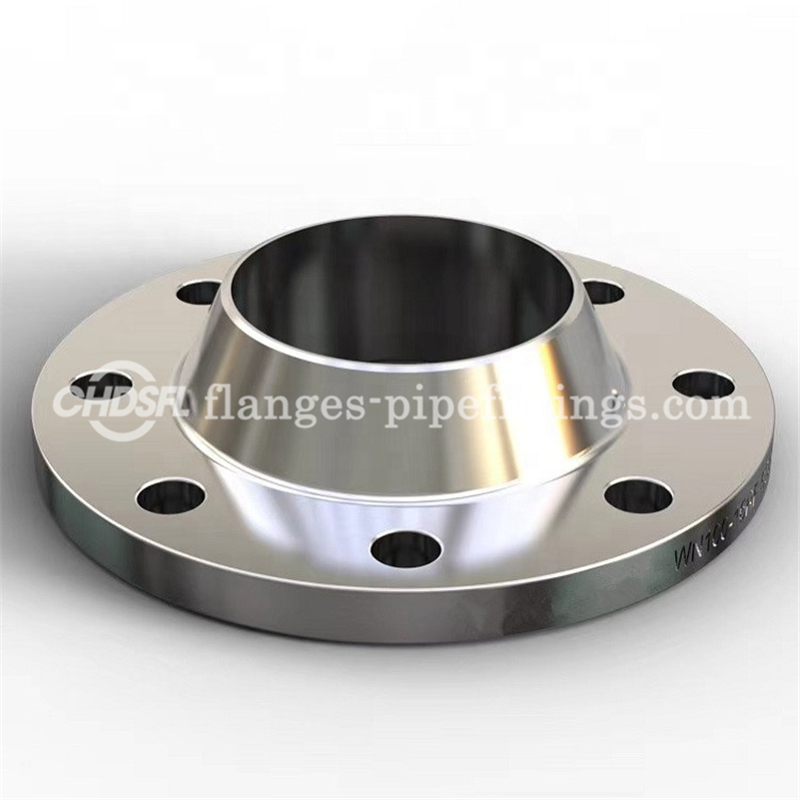

Weld Neck Flanges

Description

Weld neck flanges are the most popular type of flanges with a weld bevel at the end of the neck extension. This type of flange is designed to be butt welded directly to the pipe to provide a superior and relatively natural form connection. In larger sizes and higher pressure ratings, this is almost the only type of flange connection used. If only one drilled flange style exists in modern applications, the weld neck flange will be your flange of choice.

This kind of flange include lots of specification, Weld neck Flange is expensive because of its long neck and cost of people for contact WN flange with pipeline or fitting but is preferred for high stress applications. The necks, or hubs, transmits stresses to the pipeline.

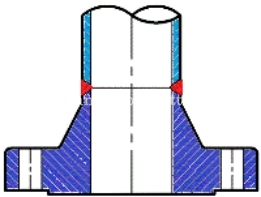

The weld bevel is attached in a V-joint to the tube end with a similar bevel, which allows for a uniform circular weld around the perimeter for a uniform transition. This allows gas or liquid within the piping assembly to flow through the flange connection with minimal restriction. Check this welded bevel connection after the welding procedure to ensure an even seal and no abnormalities.

Weld neck flange welded to pipe

The smooth transition between the flange and the hub combined with the strength

of the butt weld joint, allows the flange to be used in extreme conditions of cyclic loading, bending and temperature fluctuations

China leading Weld Neck Flanges manufacturer (www.dingshengflange.com)

one-stop OEM and manufacturing for Lap Joint Flanges in Stainless Steel