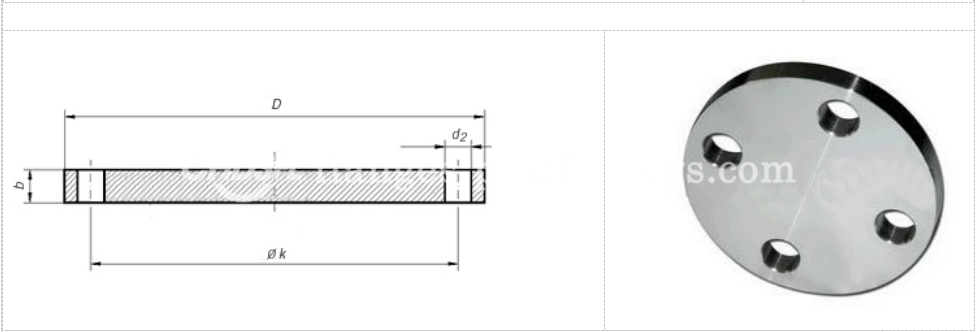

EN 1092-1 TYPE 05 BLIND FLANGE

PN6, PN10, PN16, PN25, PN40

Flange Dimensions & Approximate Masses

|

EN 1092-1 TYPE 05 PN6 BLIND FLANGE |

|||||||

|

Diameter |

Flange |

Screws |

Weight |

||||

|

k |

D |

b |

d2 |

Thread |

Bolt holes |

KG |

|

|

15 |

55 |

80 |

12 |

11 |

M10 |

4 |

0,438 |

|

20 |

65 |

90 |

14 |

11 |

M10 |

4 |

0,657 |

|

25 |

75 |

100 |

14 |

11 |

M10 |

4 |

0,821 |

|

32 |

90 |

120 |

14 |

14 |

M12 |

4 |

1,180 |

|

40 |

100 |

130 |

14 |

14 |

M12 |

4 |

1,390 |

|

50 |

110 |

140 |

14 |

14 |

M12 |

4 |

1,620 |

|

65 |

130 |

160 |

14 |

14 |

M12 |

4 |

2,140 |

|

80 |

150 |

190 |

16 |

18 |

M16 |

4 |

3,430 |

|

100 |

170 |

210 |

16 |

18 |

M16 |

4 |

4,220 |

|

125 |

200 |

240 |

18 |

18 |

M16 |

8 |

6,100 |

|

150 |

225 |

265 |

18 |

18 |

M16 |

8 |

7,510 |

|

200 |

280 |

320 |

20 |

18 |

M16 |

8 |

12,300 |

|

250 |

335 |

375 |

22 |

18 |

M16 |

12 |

18,500 |

|

300 |

395 |

440 |

22 |

22 |

M20 |

12 |

25,500 |

|

350 |

445 |

490 |

22 |

22 |

M20 |

12 |

31,800 |

|

400 |

495 |

540 |

22 |

22 |

M20 |

16 |

38,500 |

|

450 |

550 |

595 |

24 |

22 |

M20 |

16 |

51,200 |

|

500 |

600 |

645 |

24 |

22 |

M20 |

20 |

60,100 |

|

600 |

705 |

755 |

30 |

26 |

M24 |

20 |

103,000 |

|

700 |

810 |

860 |

40 |

26 |

M24 |

24 |

178,000 |

|

800 |

920 |

975 |

44 |

30 |

M27 |

24 |

252,000 |

|

900 |

1020 |

1075 |

48 |

30 |

M27 |

24 |

336,000 |

|

1000 |

1120 |

1175 |

52 |

30 |

M27 |

28 |

435,000 |

|

1200 |

1340 |

1405 |

60 |

33 |

M30 |

32 |

717,000 |

|

1400 |

1560 |

1630 |

68 |

36 |

M33 |

36 |

1.094,000 |

|

1600 |

1760 |

1830 |

76 |

36 |

M33 |

40 |

1.545,000 |

|

1800 |

1970 |

2045 |

84 |

39 |

M36 |

44 |

2.131,000 |

|

2000 |

2180 |

2265 |

92 |

42 |

M39 |

48 |

2.862,000 |

| 1. SURFACE FINISH FACING TYPES A, B1, B2 etc | |||||||

| 2. FLANGE MARKING: LOGO EN 1092-1 / 05 / DN100 / PN6 / P245GH / HEAT NUMBER | |||||||

|

EN 1092-1 TYPE 05 PN10 BLIND FLANGE |

|||||||

|

Diameter |

Flange |

Screws |

Weight |

||||

|

k |

D |

b |

d2 |

Thread |

Bolt holes |

KG |

|

|

200 |

295 |

340 |

24 |

22 |

M20 |

8 |

16,500 |

|

250 |

350 |

395 |

26 |

22 |

M20 |

12 |

24,100 |

|

300 |

400 |

445 |

26 |

22 |

M20 |

12 |

30,800 |

|

350 |

460 |

505 |

26 |

22 |

M20 |

16 |

39,600 |

|

400 |

515 |

565 |

26 |

26 |

M24 |

16 |

49,400 |

|

450 |

565 |

615 |

28 |

26 |

M24 |

20 |

63,000 |

|

500 |

620 |

670 |

28 |

26 |

M24 |

20 |

75,200 |

|

600 |

725 |

780 |

34 |

30 |

M27 |

20 |

124,000 |

|

700 |

840 |

895 |

38 |

30 |

M27 |

24 |

183,000 |

|

800 |

950 |

1015 |

48 |

33 |

M30 |

24 |

297,000 |

|

900 |

1050 |

1115 |

50 |

33 |

M30 |

28 |

374,000 |

|

1000 |

1160 |

1230 |

54 |

36 |

M33 |

28 |

492,000 |

|

1200 |

1380 |

1455 |

66 |

39 |

M36 |

32 |

842,000 |

| 1. SURFACE FINISH FACING TYPES A, B1, B2 etc | |||||||

| 2. FLANGE MARKING: LOGO EN 1092-1 / 05 / DN100 / PN10 / P245GH / HEAT NUMBER | |||||||

|

EN1092-1 TYPE05 PN16 BLIND FLANGE |

|||||||

|

Diameter |

Flange |

Screws |

Weight |

||||

|

k |

D |

b |

d2 |

Thread |

Bolt holes |

KG |

|

|

15 |

65 |

95 |

16 |

14 |

M12 |

4 |

0,813 |

|

20 |

75 |

105 |

18 |

14 |

M12 |

4 |

1,140 |

|

25 |

85 |

115 |

18 |

14 |

M12 |

4 |

1,380 |

|

32 |

100 |

140 |

18 |

18 |

M16 |

4 |

2,030 |

|

40 |

110 |

150 |

18 |

18 |

M16 |

4 |

2,350 |

|

50 |

125 |

165 |

18 |

18 |

M16 |

4 |

2,880 |

|

65 |

145 |

185 |

18 |

18 |

M16 |

4 |

3,643 |

|

80 |

160 |

200 |

20 |

18 |

M16 |

8 |

4,610 |

|

100 |

180 |

220 |

20 |

18 |

M16 |

8 |

5,650 |

|

125 |

210 |

250 |

22 |

18 |

M16 |

8 |

8,130 |

|

150 |

240 |

285 |

22 |

22 |

M20 |

8 |

10,500 |

|

200 |

295 |

340 |

24 |

22 |

M20 |

12 |

16,200 |

|

250 |

355 |

405 |

26 |

26 |

M24 |

12 |

25,000 |

|

300 |

410 |

460 |

28 |

26 |

M24 |

12 |

35,100 |

|

350 |

470 |

520 |

30 |

26 |

M24 |

16 |

48,000 |

|

400 |

525 |

580 |

32 |

30 |

M27 |

16 |

63,500 |

|

450 |

585 |

640 |

40 |

30 |

M27 |

20 |

96,600 |

|

500 |

650 |

715 |

44 |

33 |

M30 |

20 |

133,000 |

|

600 |

770 |

840 |

54 |

36 |

M33 |

20 |

226,000 |

|

700 |

840 |

910 |

58 |

36 |

M33 |

24 |

285,000 |

|

800 |

950 |

1025 |

62 |

39 |

M36 |

24 |

388,000 |

|

900 |

1050 |

1125 |

64 |

39 |

M36 |

28 |

483,000 |

|

1000 |

1170 |

1255 |

68 |

42 |

M39 |

28 |

640,000 |

| 1. SURFACE FINISH FACING TYPES A, B1, B2 etc | |||||||

| 2. FLANGE MARKING: LOGO EN 1092-1 / 05 / DN100 / PN16 / P245GH / HEAT NUMBER | |||||||

Production Capacity & Purchase Details

1. Supply Flange Dimension DN15 – DN2000 (1/2″ – 80″), Forged Flange.

2. Material Carbon Steel: P235GH, P245GH, P250GH, RST37.2, C22.8, S235JR, ST37, ASTM A105

3. Material Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 etc.

4. Flanges Anti Rust: Anti Rust Oil, Black Paint, Yellow Paint Coating, Hot Dipped Galvanized, Cold Galvanized etc.

5. Monthly Output: 3000 tons per Month.

6. Delivery Terms: CIF, CFR, FOB, EXW.

7. Payment Terms: Wire Transfer (T/T), Irrevocable L/C at Sight etc.

8. Minimum Order Quantity: 1Ton or 100Pcs.

9. Quality Guarantee: EN10204 3.1 Certificate, Mill Certificate, Third Party Inspection, Free Replacement Service.

10. Find More Requirements In Flanges Market.