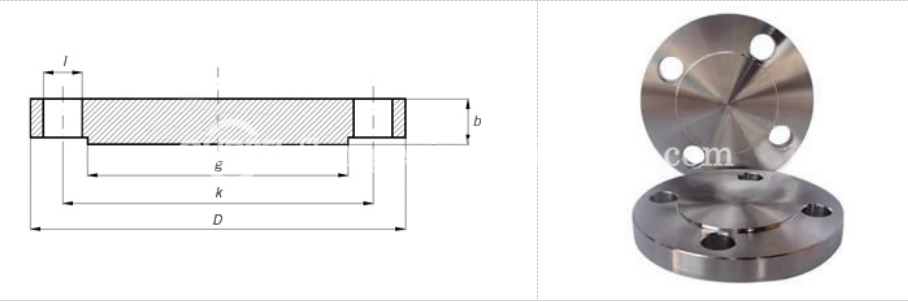

ANSI, ASME, ASA, B16.5 BLIND FLANGE RAISED FACE

CLASS 150 / 300 / 600

Flange Dimensions & Approximate Masses

|

ANSI, ASME, ASA, B16.5 150lb/sq.in. Blind Flange |

|||||||

|

ø |

D |

b |

g |

k |

Holes |

l |

Kg. |

|

1/2″ |

88,9 |

11,1 |

34,9 |

60,3 |

4 |

15,9 |

0,400 |

|

3/4″ |

98,4 |

12,7 |

42,9 |

69,8 |

4 |

15,9 |

0,700 |

|

1″ |

107,9 |

14,3 |

50,8 |

79,4 |

4 |

15,9 |

0,900 |

|

1 1/4″ |

117,5 |

15,9 |

63,5 |

88,9 |

4 |

15,9 |

1,300 |

|

1 1/2″ |

127,0 |

17,5 |

73,0 |

98,4 |

4 |

15,9 |

1,600 |

|

2″ |

152,4 |

19,0 |

92,1 |

120,6 |

4 |

19,0 |

2,600 |

|

2 1/2″ |

177,8 |

22,2 |

104,8 |

139,4 |

4 |

19,0 |

4,100 |

|

3″ |

190,5 |

23,8 |

127,0 |

152,4 |

4 |

19,0 |

5,000 |

|

3 1/2″ |

215,9 |

23,8 |

139,7 |

177,8 |

8 |

19,0 |

6,400 |

|

4″ |

228,6 |

23,8 |

157,2 |

190,5 |

8 |

19,0 |

7,100 |

|

5″ |

254,0 |

23,8 |

185,7 |

215,9 |

8 |

22,2 |

9,000 |

|

6″ |

279,4 |

25,4 |

215,9 |

241,3 |

8 |

22,2 |

11,800 |

|

8″ |

342,9 |

28,6 |

269,9 |

298,4 |

8 |

22,2 |

21,000 |

|

10″ |

406,4 |

30,2 |

323,4 |

361,9 |

12 |

25,4 |

30,000 |

|

12″ |

482,6 |

31,7 |

381,0 |

431,8 |

12 |

25,4 |

45,000 |

|

14″ |

533,4 |

34,9 |

412,7 |

476,2 |

12 |

28,6 |

59,000 |

|

16″ |

596,9 |

36,5 |

469,9 |

539,9 |

16 |

28,6 |

79,000 |

|

18″ |

635,0 |

39,7 |

533,4 |

577,8 |

16 |

31,7 |

97,000 |

|

20″ |

698,5 |

42,9 |

584,2 |

635,0 |

20 |

31,7 |

124,000 |

|

22″ |

749,3 |

46,0 |

641,2 |

692,1 |

20 |

34,9 |

151,000 |

|

24″ |

812,8 |

47,6 |

692,1 |

749,3 |

20 |

34,9 |

188,000 |

NOTE:

1. Class 150 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

|

ANSI, ASME, ASA, B16.5 300lb/sq.in. Blind Flange |

|||||||

|

ø |

D |

b |

g |

k |

Holes |

l |

Kg. |

|

1/2″ |

95,2 |

14,3 |

34,9 |

66,7 |

4 |

15,9 |

0,700 |

|

3/4″ |

117,5 |

15,9 |

42,9 |

82,5 |

4 |

19,0 |

1,200 |

|

1″ |

123,8 |

17,5 |

50,8 |

88,9 |

4 |

19,0 |

1,500 |

|

1 1/4″ |

133,3 |

19,0 |

63,5 |

98,4 |

4 |

19,0 |

2,000 |

|

1 1/2″ |

155,6 |

20,6 |

73,0 |

114,3 |

4 |

22,2 |

2,900 |

|

2″ |

165,1 |

22,2 |

92,1 |

127,0 |

8 |

19,0 |

3,400 |

|

2 1/2″ |

190,5 |

25,4 |

104,8 |

149,2 |

8 |

22,2 |

5,100 |

|

3″ |

209,5 |

28,6 |

127,0 |

168,3 |

8 |

22,2 |

7,000 |

|

3 1/2″ |

228,6 |

30,2 |

139,7 |

184,1 |

8 |

22,2 |

8,900 |

|

4″ |

254,0 |

31,7 |

157,2 |

200,0 |

8 |

22,2 |

11,800 |

|

5″ |

279,4 |

34,9 |

185,7 |

234,9 |

8 |

22,2 |

15,500 |

|

6″ |

317,5 |

36,5 |

215,9 |

269,9 |

12 |

22,2 |

21,300 |

|

8″ |

381,0 |

41,3 |

269,9 |

330,2 |

12 |

25,4 |

35,200 |

|

10″ |

444,5 |

47,6 |

323,8 |

387,3 |

16 |

28,6 |

57,000 |

|

12″ |

520,7 |

50,8 |

381,0 |

450,8 |

16 |

31,7 |

82,000 |

|

14″ |

584,2 |

54,0 |

412,7 |

514,3 |

20 |

31,7 |

106,000 |

|

16″ |

647,7 |

57,1 |

469,9 |

571,5 |

20 |

34,9 |

140,000 |

|

18″ |

711,2 |

60,3 |

533,4 |

628,6 |

24 |

34,9 |

178,000 |

|

20″ |

774,7 |

63,5 |

584,2 |

685,8 |

24 |

34,9 |

223,000 |

|

22″ |

838,2 |

66,7 |

641,2 |

742,9 |

24 |

41,3 |

270,000 |

|

24″ |

914,4 |

69,8 |

692,1 |

812,8 |

24 |

41,3 |

345,000 |

NOTE:

1. Class 300 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

5. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

|

ANSI, ASME, ASA, B16.5 600lb/sq.in. Blind Flange |

|||||||

|

ø |

D |

b |

g |

k |

Holes |

l |

Kg. |

|

1/2″ |

95,2 |

14,3 |

34,9 |

66,7 |

4 |

15,9 |

0,700 |

|

3/4″ |

117,5 |

15,9 |

42,9 |

82,5 |

4 |

19,0 |

1,200 |

|

1″ |

123,8 |

17,5 |

50,8 |

88,9 |

4 |

19,0 |

1,500 |

|

1 1/4″ |

133,3 |

20,6 |

63,5 |

98,4 |

4 |

19,0 |

2,000 |

|

1 1/2″ |

155,6 |

22,2 |

73,0 |

114,3 |

4 |

22,2 |

3,200 |

|

2″ |

165,1 |

25,4 |

92,1 |

127,0 |

8 |

19,0 |

4,300 |

|

2 1/2″ |

190,5 |

28,6 |

104,8 |

149,2 |

8 |

22,2 |

6,000 |

|

3″ |

209,5 |

31,7 |

127,0 |

168,3 |

8 |

22,2 |

8,000 |

|

3 1/2″ |

228,6 |

34,9 |

139,7 |

184,1 |

8 |

25,4 |

10,500 |

|

4″ |

273,0 |

38,1 |

157,2 |

215,9 |

8 |

25,4 |

18,000 |

|

5″ |

330,2 |

44,4 |

185,7 |

266,7 |

8 |

28,6 |

28,500 |

|

6″ |

355,6 |

47,6 |

215,9 |

292,1 |

12 |

28,6 |

35,500 |

|

8″ |

419,1 |

55,6 |

269,9 |

349,2 |

12 |

31,7 |

58,000 |

|

10″ |

508,0 |

63,5 |

323,8 |

431,8 |

16 |

34,9 |

98,000 |

|

12″ |

558,8 |

66,7 |

381,0 |

488,9 |

20 |

34,9 |

125,000 |

|

14″ |

603,2 |

69,8 |

412,7 |

527,0 |

20 |

38,1 |

151,000 |

|

16″ |

685,8 |

76,2 |

469,9 |

603,2 |

20 |

41,3 |

215,000 |

|

18″ |

742,9 |

82,5 |

533,4 |

654,0 |

20 |

44,4 |

287,000 |

|

20″ |

812,8 |

88,9 |

584,2 |

723,9 |

24 |

44,4 |

366,000 |

|

22″ |

869,9 |

95,2 |

641,2 |

777,9 |

24 |

47,6 |

437,000 |

|

24″ |

939,8 |

101,6 |

692,1 |

838,2 |

24 |

50,8 |

532,000 |

NOTE:

1. Class 600 flanges except Lap Joint will be furnished with 0.25 (6.35mm) raised face, which is not included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

2. For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

3. Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

4. The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

5. Dimensions of sizes 1/2 through 3 1/2 are the same as for Class 400 Flanges.

6. Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

Production Capacity & Purchase Details

1. Supply Flange Dimension DN15 – DN2000 (1/2″ – 80″), Forged Flange.

2. Material Carbon Steel: ASTM A105, A181, A350 LF1, A350LF2, A350LF3, A36, A234 WPB, Q235B, 20#, 20Mn etc.

3. Material Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 etc.

4. Flanges Anti Rust: Anti Rust Oil, Black Paint, Yellow Paint Coating, Hot Dipped Galvanized, Cold Galvanized etc.

5. Monthly Output: 3000 tons per Month.

6. Delivery Terms: CIF, CFR, FOB, EXW.

7. Payment Terms: Wire Transfer (T/T), Irrevocable L/C at Sight etc.

8. Minimum Order Quantity: 1Ton or 100Pcs.

9. Quality Guarantee: EN10204 3.1 Certificate, Mill Certificate, Third Party Inspection, Free Replacement Service.

10. Find More Requirements In Flanges Market.