Custom Standard And Non-standard Flanges ASME B16.47 Class 900 Series A Welding Neck Flanges

Video

Description

Flange manufacturers on the market in the production of flanges, is to be in accordance with the standard to produce, and also more in accordance with the national standard to produce flanges, that is: in accordance with the national standard requirements of the size, tolerance range, etc. production flange, such a standard flange in use, although also can be used, but more often than not, industrial production requirements of the flange is not the same, so that the flange specifications will also change, such as the Industrial production will not be able to use the standard flange, can only use large flanges; some industrial production can only use smaller flanges to use, so, in the face of such a situation, the standard flange on the market is no longer applicable, can only be customized to get the desired flange.

Custom flanges, belonging to the pipeline engineering in the custom products. OEM is due to the needs of the pipeline engineering design and site construction needs. Custom pipeline fittings to facilitate the use of non-standard pipeline projects, standard pipeline projects in the disassembly and later construction continuity, are to use to custom pipeline fittings, custom flanges.

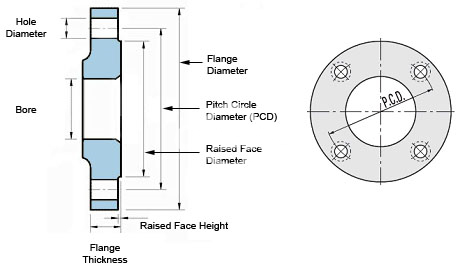

For a custom ring flange, all we need is the OD, ID, thickness, bolt pattern, and grade of material. Get us that information and we can quote for as few as ONE piece – yes, there’s no minimum quantity even on customs (though large quantities will of course receive discounts due to set up costs being distributed more widely).

What are the advantages and disadvantages of using custom flanges?

Better Performance

Custom flanges can be designed to provide the customer with the size or construction required for the application, with low machining errors.

Longer Durability

Custom flanges are typically made with quality materials and construction techniques. This results in flanges that last longer than standard flanges and can withstand harsher environments.

Flange Finish

Sometimes, the finish of a flange is as important as its performance. The surface roughness of the flange sealing surface is one of the most important factors affecting the sealing performance. Some people have tested, when the flange sealing surface roughness of about Ra3.2μm, with metal wrapped asbestos gasket sealing pressure of 0.49MPa air, found a micro-leakage phenomenon; when the value of the surface roughness is reduced to 1.6μm, it can be sealed.

In various flange standards, the surface roughness of the sealing surface is required, but because of the wide variety of gaskets and different roughness requirements, the standards cannot be specified one by one. When using metal flat gasket, metal toothed gasket, metal waveform gasket and metal pack gasket, the surface roughness of flange sealing surface needs Ra3.2-1.6μm, which is difficult for the processing of large diameter flange surface.

Because custom flanges are not limited to standard designs, they can be used for a wider range of applications. This provides you with greater flexibility in selecting flanges as needed.

China leading Stainless Steel Flange manufacturer (www.dingshengflange.com)

one-stop OEM and manufacturing for Lap Joint Flanges in Stainless Steel.