CE Certification Tongue And Groove Flange Exporter – Socket Weld Flanges – DS PIPE

CE Certification Tongue And Groove Flange Exporter – Socket Weld Flanges – DS PIPE Detail:

Description

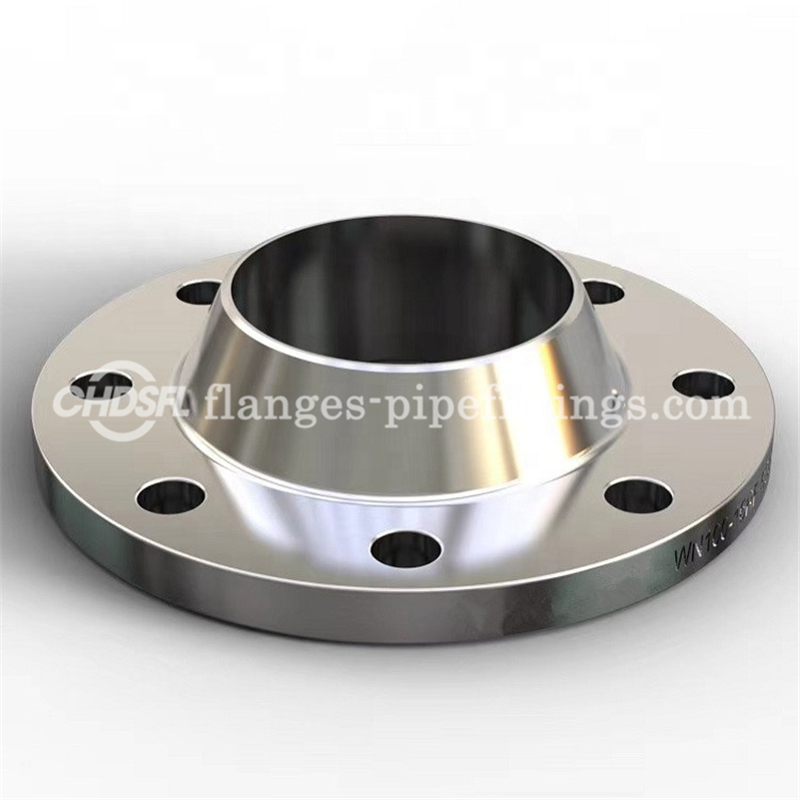

Socket weld flanges are a less common but equally effective connection for flanges which require less overall available space than a traditional weld neck flange, with a counterbore in the center to allow for a clean weld of pipe into the socket.

Usually furnished in smaller nominal pipe sizes, these make an excellent alternative to weld necks and slip-ons when necessary. An assembly with limited space may be an instance in which a socket weld is selected, provided the pressure class is comparatively low and the fluid is not corrosive or for extremely high temperature service.

These socket flanges connect to square end pipe with a fillet weld at the ID of the hub of the socket, as the pipe is designed to sit almost flush against the counter bore of the flange. The expansion gap between the end of the pipe and the counter bore leaves just enough space for the welder to adjust the pipe within the connection. It is important to note that a butt weld pipe connection is not recommended for suiting to a socket counter bore connection when a square end pipe connection is possible.

The inner bore of the slip on flange is a little larger than the pipe OD,to make sure the pipe or fitting end can slip into the flange.The slip on flange is fillet welded with the pipe or fitting,different with the butt welding method of weld neck flange, and the pipe no need to do the bevel end,just square end is ok for welding,this is also different.Commonly,the slip on flange can be fillet welded with the pipe on the two sides.It can make sure the joint quality with the pipe.

The advantage of socket weld flanges is their simple design, they are well suited for small pipe size applications e.g. 2 inches (5cm) and below, and for non-critical applications e.g. non-hazardous systems; they are not suitable for highly erosive or corrosive systems.

China leading Socket Weld Flanges manufacturer (www.dingshengflange.com)

one-stop OEM and manufacturing for Lap Joint Flanges in Stainless Steel

Product detail pictures:

Related Product Guide:

Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for CE Certification Tongue And Groove Flange Exporter – Socket Weld Flanges – DS PIPE , The product will supply to all over the world, such as: Greenland, French, Hungary, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.