CE Certification Stainless Steel Weld Elbows Manufacturers – Steel Pipe Elbow – DS PIPE

CE Certification Stainless Steel Weld Elbows Manufacturers – Steel Pipe Elbow – DS PIPE Detail:

Description

Steel pipe elbow is an important parts in plumbing pipeline systems and used to change the fluid directions. It ranges in different types as per body material there are stainless steel elbow, carbon steel elbow, and alloy steel; As per fluid directions there are 45 degree, 90 degree elbow and 180 degree; As per elbow length and radius there are short radius elbow (SR elbow) and long radius elbow (LR elbow); As per connections types there are butt weld elbow, socket weld elbow and threaded steel piping elbow.

90 Degree Steel Pipe Elbow is the most used type.

90 degree steel pipe elbow is to change fluid direction by 90 degree, also called the vertical elbow, it is the most used type in all the pipeline systems, since it is easy to compatible with the steel construction and structural.

Process: (Cold&Mandrel Forming).

Sizes : (Seamless Type): 1/2″ -20″ (DN15-DN500).

(Welded Type): 1/2” -48″ (DN15-DN1200).

Standards:GB/T12459, GB/T13401. SH3408, SH3409.

ASME/ANSI B16.9, B 16.28, ASTM A403, MSS SP-43.

DIN 2605, DIN2609, DIN2615, DIN2616.

JIS B2311, JIS B2312, JIS B2313.

Schedules: Sch5S-Sch80S; Sch10-Sch160; XS-XXS.

Materials: TP304; TP3O4H; TP304L; TP316; TP316L.

TP321; TP321H; TP317L; TP310S; TP347H.

• 90 degree elbow of long radius.

This kind of 90 degree steel pipe elbow is installed between different lengths of pipe or tubing.

It helps to change the direction at an angle of 90 degrees. It’s often used for connection of hoses to water pumps, deck drains, and valves.

• 90 degree elbow of short radius

The main use is just like the previously stated pipe, but the diameter is short. So this kind of piping elbow is often used when shortage of space.

45 degree steel pipe elbow.

45 degree elbow is to change pipe direction by 45 degree, it is second common used type in industrial pipelines.

Process: (Cold&Mandrel Forming)

Sizes : (Seamless Type): 1/2″ -20″ (DN15-DN500)

(Welded Type): 1/2” -48″ (DN15-DN1200)

Standards: GB/T12459, GB/T13401. SH3408, SH3409;

ASME/ANSI B16.9, B 16.28, ASTM A403, MSS SP-43;

DIN 2605, DIN2609, DIN2615, DIN2616;

JIS B2311, JIS B2312, JIS B2313

Schedules: Sch5S-Sch80S; Sch10-Sch160; XS-XXS

Materials: TP304; TP3O4H; TP304L; TP316; TP316L; TP321;TP321H; TP317L; TP310S; TP347H

• 45 degree LR steel elbow.

This kind of elbow is installed between two pipes so that the direction could be changed at an angle of 45 degrees. Since it creates lower frictional resistance, pressure also be lower.

• 45 degree SR elbow.

This kind of elbow is usually attached to copper, plastic, steel, cast iron, and lead. It could also be attached to clamps of stainless steel and rubber. As a result, it’s widely used in chemical, food, facilities of water supply, electronic industrial and chemical pipelines, gardening and agriculture production, piping for solar power facilities, and pipelines for air conditioning.

180 degree steel elbow.

This kind of elbow helps to change the direction at an angle of 180 degrees. Since it usually results in low pressure, its applications is limited to minimum deposition and low turbulence systems.

Process: (Cold&Mandrel Forming)

Sizes : (Seamless Type): 1/2″ -20″ (DN15-DN500)

Standards:GB/T12459, GB/T13401. SH3408, SH3409;

ASME/ANSI B16.9, B 16.28, ASTM A403, MSS SP-43; DIN 2605, DIN2609, DIN2615, DIN2616; JIS B2311, JIS B2312, JIS B2313

Schedules: Sch5S-Sch80S

Materials: TP304; TP3O4H; TP304L; TP316; TP316L; TP321; TP321H; TP317L; TP310S; TP347H

• Reducer Elbow.

Also known as decreasing elbow, is a kind of pipe which applied when both the elbow and closures are different in size. It’s often used so that different sizes of the pipes could be easily distinguished in order to make noteworthy turns.

Process: (Cold&Mandrel Forming).

Sizes : (Seamless Type): 1/2″ -20″ (DN15-DN500).

(Welded Type): 1/2” -48″ (DN15-DN1200).

Standards: GB/T12459, GB/T13401. SH3408, SH3409.

ASME/ANSI B16.9, B 16.28, ASTM A403, MSS SP-43.

DIN 2605, DIN2609, DIN2615, DIN2616.

JIS B2311, JIS B2312, JIS B2313.

Schedules: Sch5S-Sch80S; Sch10-Sch160; XS-XXS

Materials: TP304; TP3O4H; TP304L; TP316; TP316L; TP321; TP321H; TP317L; TP310S; TP347H.

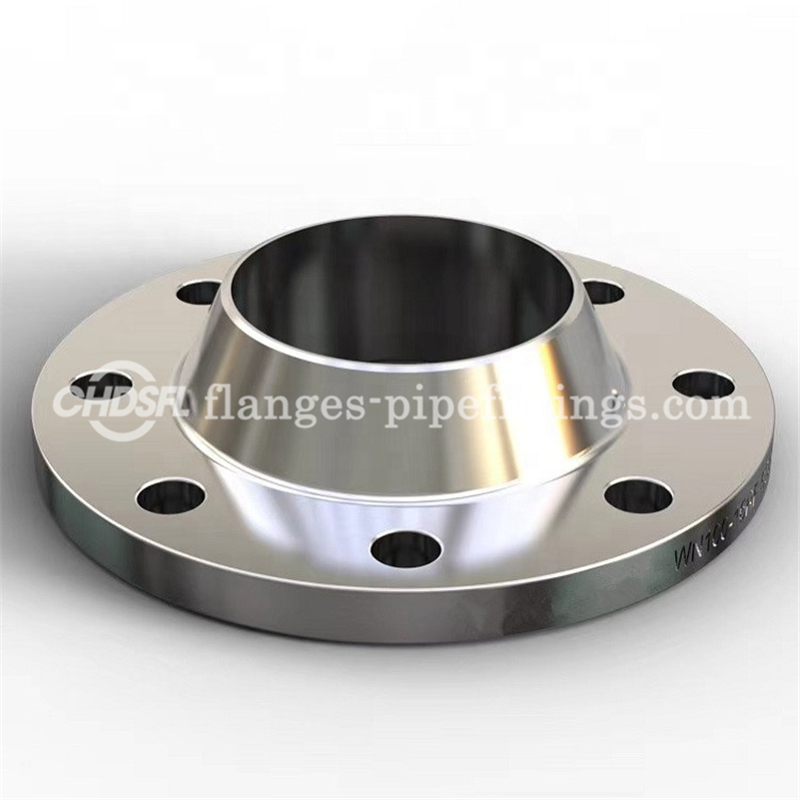

Butt weld elbow – Most common connection type

The easiest way to connect the elbow and pipe is to do welding directly to the elbow ends with pipe ends, where we called butt to butt weld (BW Elbow, as showed in above picture). Butt weld elbow mainly used in a higher pressure and temperature than the other connection types of elbow. (Than socket weld elbow or the threaded piping elbow)

Stainless steel elbow material in stainless (Added Cr and Ni chemicals in carbon steel), standards and grades commonly in ASTM A403 WP 304/304L, 316/316L, ASTM A270 etc. It has higher strength and higher corrosion-resistances than carbon steel elbow.

Surface treatment in 2B or mirror, these are usually used in food industries and sanitary purposes.

For general surface treatment stainless steel elbow commonly used in high corrosion environment in chemical plants or offshore oil and gas pipelines.

Product Testing

Part Of The Process

Product detail pictures:

Related Product Guide:

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for CE Certification Stainless Steel Weld Elbows Manufacturers – Steel Pipe Elbow – DS PIPE , The product will supply to all over the world, such as: Croatia, Sevilla, Durban, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!