CE Certification Backing Flange Manufacturer – Threaded Flanges – DS PIPE

CE Certification Backing Flange Manufacturer – Threaded Flanges – DS PIPE Detail:

Description

Threaded flanges, also sometimes referred to as companion flanges / screw flanges / NPT flanges, contain a female NPT thread in the center for connection to male NPT threaded piping. Threaded flanges are common when creating reducing connections. Other thread styles are available for machining, aside from the standard NPT form as designated by the ASME B16.5 specification.

Even though the threaded flange design is available in many sizes and pressure ratings, it is mainly used for small sized piping systems i.e. ≤ 4 inches. Its usage is also typically restricted to non-toxic systems, low pressure systems, and low temperature systems. ½ inch to 2-inch size threaded flanges are much more common than sizes of 2 inches and above. Due to their lower pressure applications, threaded flanges use flat and raised faces only. They are not suitable for high temperature applications because the thread geometry would distort, which often leads to leakage.

The major advantage with threaded flanges is that they can be connected to a pipe without the need for welding. Forming joints without needing to weld is a considerable advantage, and is essential in some locations and industries e.g. explosive areas (Ex rated areas) such as petrol stations, hexagon plants, stores with flammable fluids etc. If no welding is required, a potential source of ignition is removed. Another advantage is that it is quicker and easier to assemble and disassemble a threaded flange joint than a welded flange joint.

Threaded flanges are not suitable for pipes that have a thin wall thickness, since cutting a thread on such pipes is difficult. In some cases, a seal weld may be used to increase the flange’s integrity and reduce the likelihood of leakage. Adding a seal weld will increase the flange’s integrity, but it also makes the joint more difficult to assemble and disassemble (because the weld makes it a permanent joint).

China leading Threaded flanges manufacturer ((www.dingshengflange.com))

one-stop OEM and manufacturing for Threaded flanges in Stainless Steel.

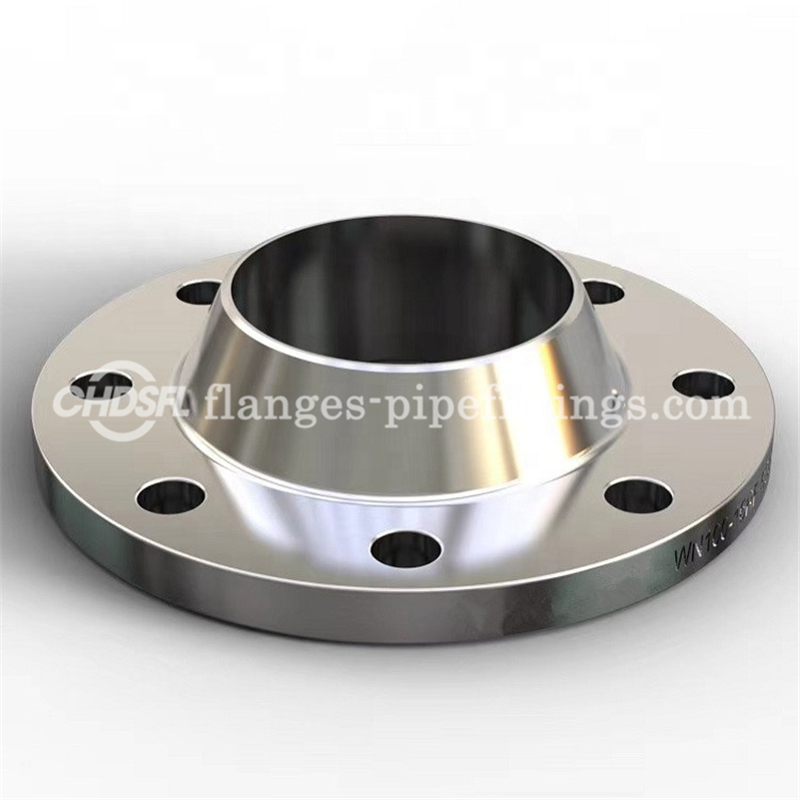

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for CE Certification Backing Flange Manufacturer – Threaded Flanges – DS PIPE , The product will supply to all over the world, such as: Romania, France, Washington, Adhering to the management tenet of "Managing Sincerely, Winning by Quality", we try our best to provide excellent products and service to our clients. We look forward to making progress together with domestic and international clients.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,